Our 24??media Ideas

Our 24??media Ideas

Blog Article

9 Simple Techniques For 24??media

Table of ContentsThings about 24??mediaThe Definitive Guide to 24??mediaAll about 24??mediaExamine This Report on 24??mediaFascination About 24??mediaFascination About 24??media

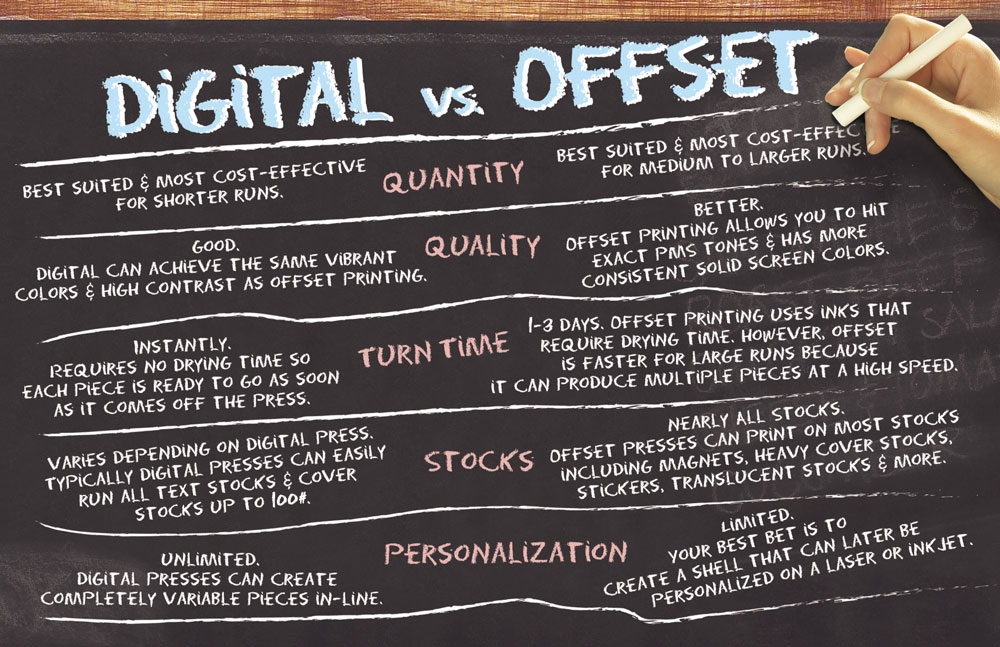

This is just feasible with Digital Printing, and it brings about a new level of personalization. Litho Lamination (Offset Printing) is a conventional printing technique and was one of the most popular option until just recently. Litho is the process of printing onto a paper lining board, and afterwards laminating that onto corrugated.Here are some of the most noteworthy ones: Even though various other printing types, like balanced out and screen, can produce great high quality, digital printing offers outstanding results. Unlike a few other techniques, the top quality of an initial item coincides as the last. The digital printing process entails a straight transfer of the ink to the substratethat's why it's much quicker than various other printing choices.

Digital printing is highly cost-effective. When it comes to customising a print task's final item, digital printing is rapid and versatile.

9 Simple Techniques For 24??media

That's why electronic printing is a recommended approach for volatile printing jobs. Digital printing entails pressing a couple of buttons and getting an outcome within secs. It doesn't need any kind of special skills or expertise to get the job donethe process is totally automated. Digital inkjet printing cuts the quantity of waste due to the fact that it just sends ink to the parts to be published.

While digital printing is highly helpful, various other methods are still in use. One of them is balanced out printing. Balanced out printing (or countered presses) is a typical printing approach. It uses publishing plates, rubber blankets, and ink. Aluminium layers transfer a picture onto a rubber blanket, which consequently rolls over a sheet of paper, leaving a print.

24??media Things To Know Before You Buy

Display printing does not apply stress to the material. That's why it's frequently used for printing on fragile substrates like balloons or thin fabrics. Digital Printing. A more vivid, saturated, and bright finishBetter colour matching capabilitiesCost-efficient for huge batches Complicated and taxing setupHigh prices for low-volume printingOnly one design per batchResolution of pictures is generally reduced top quality

The printer sprays various tiny ink beads on the surface to produce the preferred photo. Today, industrial inkjet printer innovation is replacing standard high-speed printing presses.: Laser printers use a laser to move the digital picture to the surface area. The laser moves back and forth to develop fixed electrical energy throughout the printing procedure, launching the warmed toner onto the surface.

Printer are much faster but sometimes come with higher upfront costs. Nonetheless, printer tend to have a higher long-term ROI than inkjet printers. Digital printing is developing swiftly. Many thanks to its rate, cost-efficiency, and high quality, it's most likely to make older printing technologies ineffective in the future. By maximizing digital printing abilities, you can develop premium items and advertising and marketing products while maintaining the online reputation of a modern firm.

When preparing for your organization's functional or promotional print product, it is vital to select the most efficient type of printing approach. Aspects that go into deciding the print procedure a project requirements will certainly be described in this article.

24??media - Truths

This printing procedure is primarily made use of for smaller sized projects with a quick turn-around time. Offset printing is the process where the picture is moved from a steel printing plate to a rubber covering, and after that to the paper to produce a top notch, clear photo. Countered printing is made use of for bigger tasks that need precise colour this contact form representation.

Although quotes can vary based on a task's needs, a helpful guide to deciding which printing procedure your task needs is to calculate run length. If your task needs less than 1,000 copies, it might be best to publish making use of digital presses. If the project calls for greater than 1,000 duplicates printed, it may be extra inexpensive to make use of balanced out printing.

Digital printing has a low set up price and a high run-cost, indicating it is the ideal printing method for much shorter runs. The factor that digital printing has a reduced set up expense is due to the fact that plates do not need to be made and examples do not have actually to be printed. The toner that electronic presses utilize is expensive, which is the reason why it has a greater run-cost.

Balanced out presses are made for projects with futures since they have a high set up cost and a reduced run-cost. The reason that counter printing has a high set-up expense is because journalism requires large steel plates to be made in order to transfer the picture. It has an intensive cleansing and upkeep procedure that needs to be done between various projects.

The Of 24??media

Instances of countered printing tasks produced at Printing Unlimited. Throughout the printing procedure electronic presses, like laser printers, utilize printer toner for the manufacturing of colour.

Points of personalisation can consist of a text, images or colours that connect to the customer's passion. There is a wide array of substratums that can be made use of when printing digitally on a flatbed press. Wallpaper. Using our digital printers, we are able to publish on almost any substrate approximately two inches thick

Discover Phillip Akhzar's journey, the Founder and CEO of Arka, bringing 16 years of knowledge in packaging and supply chain logistics. Learn more on Arka. Display printing a long-lasting traditional print technique, has weathered the evolving print landscape in time; this technique includes transferring ink via a mesh display onto a surface area, producing vibrant and durable prints.

In spite of its advantages, display printing has restrictions. One disadvantage is the complexity and cost of establishing initial displays. For small-scale projects, setup expenditures can be reasonably high, making it much less cost-effective than alternative techniques. Duplicating detailed details positions a challenge. While excelling in vibrant styles, display printing might have a hard time with fine information and complex patterns, a consideration for tasks requiring high intricacy.

All about 24??media

Quick Turnaround: Considering that electronic printing is relatively quicker contrasted to the traditional methods, no time will certainly be occupied by screen preparation, consequently, making it suitable for the completion of time-bound jobs that might need changes in the nick of time. Flexibility in Materials: Using electronic printing, one can publish on materials like paper, fabric, plastic, and numerous others.

Restricted Color-Matching: When it come to shade, electronic printing can not specifically replicate the shades used just like in traditional display printing. This restriction will certainly impact job calling for an excellent suit with the shades made use of in the screen printing procedure. Long-Term Longevity: Having the capacity to publish in a way that is both vivid and comprehensive, one could say that the lasting resilience of these prints on certain materials can be questionable, with many events having actually liked screen printing for its more robust, long-term outcome.

Report this page